Hordhac Product

Mashiinnada daabacaadda feerka taxanaha ee STC waxaa soo saara warshadda mishiinka Qiaosen, taasoo loo dhisay inay buuxiso ama dhaafto heerarka saxda ah ee fasalka 1-aad ee JIS. Mashiinka feerka ee Qiaosen wuxuu qaataa nidaamka Saliidda qasabka ah ee kormeeraha caadiga ah wuxuu hubinayaa isku halaynta hawlgalka.

Gap-gaab-saxaafadeed ka samaysan bir bir ah oo xoog badan iyo Quenching & shiididda Habka-Hagaha, kaas oo ka dhigi kara mashiinka saxafada inuu yareeyo leexinta iyo saxnaanta sare oo bixiya nolol qalabaysan oo kordhay.

Qalabka madbacadaha crankshaft waxaa laga been abuurtay 42CrMo alloy , qalab sax ah oo lagu farsameeyay iyo qaybaha kale ee tareenka waxaa loogu talagalay gudbinta koronto siman, hawlgal xasilloon iyo nolol dheer. Taxanaha STC mashiinka saqafka labajibbaaran waa nidaam qallalan oo qallalan, kaas oo leh nolol adeeg dheer oo nidaamka xajinta, heerka sare ee hal istaroogga iyo waxqabadka sare ee soo-saarka.

Siemens-ku-saldhigga kontoroolka iyo is-dhex-galka hawlgalka shaashadda taabashada-saaxiibtinimada leh ayaa lagu jaangooyay dhammaan mashiinnada saxaafadda saxda ah ee QIAOSEN. Way fududahay in lagu dhex daro nidaamka kale ee otomaatiga ah (sida wareejinta saxaafadda iyo robots) Noocyada kale ee xakamaynta ayaa la diyaarin karaa marka la codsado.

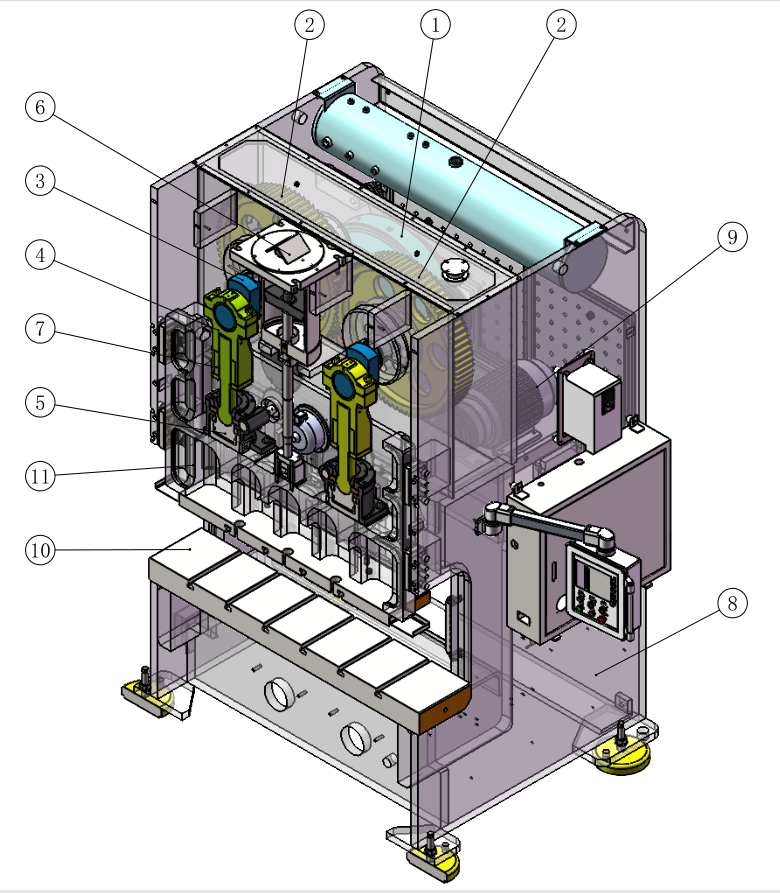

Faahfaahinta Alaabta

① Flywheel, Brake Clutch Qalalan, Gear Shaft (Nidaamka Gudbinta)

② Qalabka ugu muhiimsan

③ Gacan-qabsiga

④ Isku xidhka Ulaha

⑤ Ilaalinta Culayska Haydarooliga

⑥ dheellitir

⑦ hagaajinta lowska

⑧ Frame

⑨ Matoorka ugu muhiimsan

⑩ Xoojinta

⑪ Qaab-dhismeedka Slide

Tilmaamaha

Halbeegga farsamada

| Tilmaamaha | Unug | STC-110 | STC-160 | STC-200 | STC-250 | STC-315 | |||||

| Habka | Nooca V | Nooca H | Nooca V | Nooca H | Nooca V | Nooca H | Nooca V | Nooca H | Nooca V | Nooca H | |

| Awoodda saxaafadda | Ton | 110 | 160 | 200 | 250 | 315 | |||||

| Dhibic tonna lagu qiimeeyay | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Salaax garaac daqiiqaddii | SPM | 35 ~ 65 | 50 ~ 100 | 30 ~ 55 | 40 ~ 85 | 25 ~ 45 | 35 ~ 70 | 20 ~ 35 | 30 ~ 60 | 20 ~ 40 | 40 ~ 50 |

| Dhererka istaroogga dulsaar | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 280 | 170 |

| Dhimashada ugu badan | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 605 |

| Qadarka hagaajinta islaaydh | mm | 100 | 100 | 120 | 120 | 120 | |||||

| Aagga slide | mm | 1400*500 | 1600*550 | 1850*650 | 2100*700 | 2200*700 | |||||

| Dhumucda simbiriirrada | mm | 70 | 70 | 95 | 95 | 95 | |||||

| Aagga Xoojinta | mm | 1800*650 | 2000*760 | 2400*840 | 2700*900 | 2800*900 | |||||

| Dhumucda Xoojinta | mm | 130 | 150 | 170 | 170 | 190 | |||||

| Platform ilaa masaafada dhulka | mm | 830 | 990 | 1070 | 1100 | 1100 | |||||

| Awoodda barkinta | Ton | 3.6*2 set | 6.3*2 set | 10*2 set | 14*2 set | 14*2 set | |||||

| Awoodda dhaqdhaqaaqa ugu weyn | KW*P | 11*4 | 15*4 | 18.5*4 | 22*4 | 30*4 | |||||

| Cadaadiska hawada | kg*cm² | 6 | 6 | 6 | 6 | 6 | |||||

| Heerka saxnaanta saxaafadda | Darajo | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | |||||

| Cabirka saxaafadda (L*W*H) | mm | 1745*2000*3059 | 1940*2200*3709 | 2235*2620*3849 | 2545*3000*4304 | 2545*3100*4304 | |||||

| Cadaadis culeyska | Tan | 14.2 | 22 | 30.5 | 40.5 | 48 | |||||

| Barkinta aagga firfircoon | mm² | 350*235*2 set | 410*260*2 set | 540*350*2 set | 640*470*2 set | 690*470*2 set | |||||

| Shirkadeena waxay diyaar u tahay inay qabato shaqada cilmi baarista iyo hagaajinta wakhti kasta. Sidaa darteed, sifooyinka naqshadaynta cabbirka ee lagu qeexay buug-yarahaan waa la bedeli karaa ogeysiis dheeraad ah. | |||||||||||

● Laydh bir ah oo hal-xabo ah oo culus, oo yaraynaya leexinta, saxnaanta sare.

● OMPI oof-wareenka xajinta qalalan, nolol adeeg oo dheer.

● 6 dhibcood hagitaan slide ah, Qaado Dejinta & Shuruudda Hannaanka Tusaha-Slide, kaas oo ka dhigi kara mashiinka saxafada sare saxsanaanta & xirashada hoose iyo bixinta nolol qalabeed oo kordhay.

● La been abuurtay 42CrMo Alloy shaft crankshaft, xooggeedu 1.3 jeer ayuu ka sarreeyaa kan #45 birta ah, nolosha adeeguna way dheertahay.

Gacanka Copper wuxuu ka samaysan yahay fosfooraska bronze ee ZQSn10-1, kaas oo leh xoog 1.5 jeer ka sarreeya kan caadiga ah ee BC6.

● Qalabka ilaalinta culeyska xad dhaafka ah ee haydarooliga xasaasiga ah, si wax ku ool ah u ilaaliyo nolosha adeegga madbacadaha iyo qalabka.

● Lagu dhisay heerka saxda ah ee darajada JIS.

● Barkinta Dhinta Ikhtiyaarka ah.

Habaynta Heerka

| > | Nidaamka hawlgalka QS | > | Qalabka ilaalinta ee heerka labaad soo dhacaya |

| > | Qalabka ilaalinta culayska badan ee Haydarooliga | > | Qalabka hawada afuufaya |

| > | Qalabka kamaradaha elektarooniga ah | > | Cagaha makaaniga ah ee naxdinta leh |

| > | Qalabka hagaajinta slider koronto | > | Qalabka lagu ogaanayo quudinta xun ayaa loo hayaa interface |

| > | Matoorka xawaaraha bedbeddelka soo noqnoqda ee isbedbeddelaya (xawaaraha la hagaajin karo) | > | Qalabka dayactirka iyo sanduuqa qalabka |

| > | Qalabka hawada afuufaya | > | Qalabka ugu weyn ee matoorka roga |

| > | Tilmaamaha dhererka dhinta dhijitaalka ah | > | Daah Fudud (Ilaalinta Badbaadada) |

| > | Qalab dheeli tiran oo sibraar iyo shaabadeynaya | > | Korontada |

| > | Xakamaynta kamarada wareega | > | Qalabka saliidda dufanka korontada |

| > | Tilmaamaha xagasha crankshaft | > | Shaashadda taabashada (ka hor nasasho, hore u rari) |

| > | Miisaanka Electromagnetic | > | Console laba-gacanood ah oo shaqaynaysa oo go'an |

| > | Xidhiidhiyaha isha hawada | > | Nalalka dhimanaya LED |

Qaabaynta Ikhtiyaarka

| > | Waxka bedelka Shuruudaha Macmiilka | > | Nooca T-koonsole la dhaqaajin karo |

| > | Die Kushion | > | Saliidda saliidda ee dib-wareega ah |

| > | Lugaha beddelka | > | Xajin qoyan |

| > | Nidaamka Isbeddelka Dhimashada Degdegga ah | > | Go'doon ka-hortagga gariirka |

| > | Slide garaac qalabka | > | Kormeerka Tonnage |

| > | Nidaamka Turnkey oo leh Khadka Qudinta Gariiradda iyo Nidaamka Automation-ka |